Availability

To calculate availability, we can use Run Time / Planned Production Time, where Run Time is the Planned Production Time minus any outages.

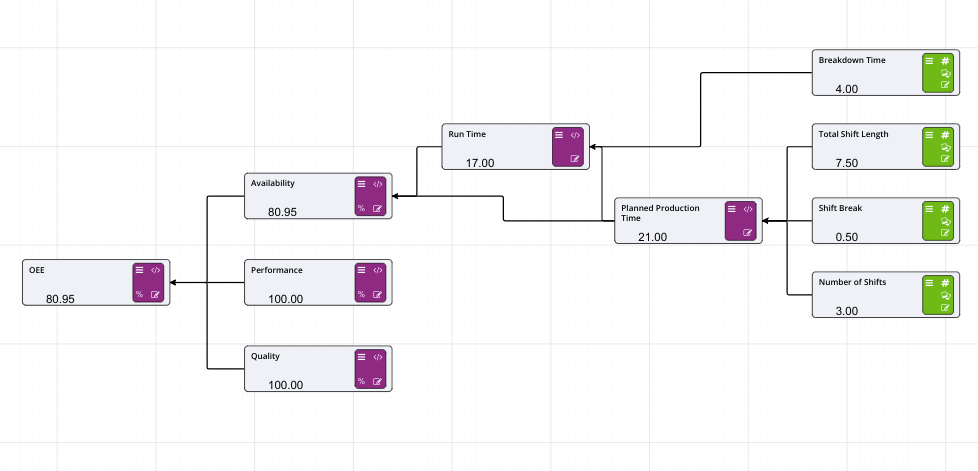

- Create a new calculation node to the right of Availability called Run Time, and another, further right, called Planned Production Time.

- Link these nodes to Availability, and change the availability calculation to

[Run Time] / [Planned Production Time]. You will notice that the OEE and availability calculations now error out. That is because Run Time and Planned Production Times have no calculations. - Create a number of input nodes to the right of the calculation nodes, called Breakdown Time, Total Shift Length, Shift Break and Number of Shifts.

- Our Planned Production time is

[Number of Shifts] * ( [Total Shift Length] - [Shift Break]) - Our Runtime is

[Planned Production Time] - [Breakdown Time]