Analysis - Rail

- Go to the Port page, and ensure the timeslider at the bottom of the page is set to period 0.

- You will notice that the ship schedule is due to remove 300,000 tonnes from the Port Stockpile. The Shipped Closing Balance indicates we have achieved this, and the Port Stockpile closing balance is reduced to 120,000.

- Step through time by clicking the right arrow of the time slider, you will notice that the Port Stockpile Closing Balance gradually increases as each 30,000 tonne increment is railed into the port. At period 6, another ship arrives, but we don’t have enough product on teh Port Stockpile to service this request (we should only have 150,000). This means there is not enough product being railed.

- Create a new scenario by cloning the baseline scenario, and call it Increase Rail Schedule. Cloning the scenario allows us to always step back to the baseline if we need to.

- Click on the Rail page, and open the Rail Schedule.

- Click on the Rail Schedule, open up the properties and change the scope to Scenario (this can be done through the Research Grid, or through the Node Properties.

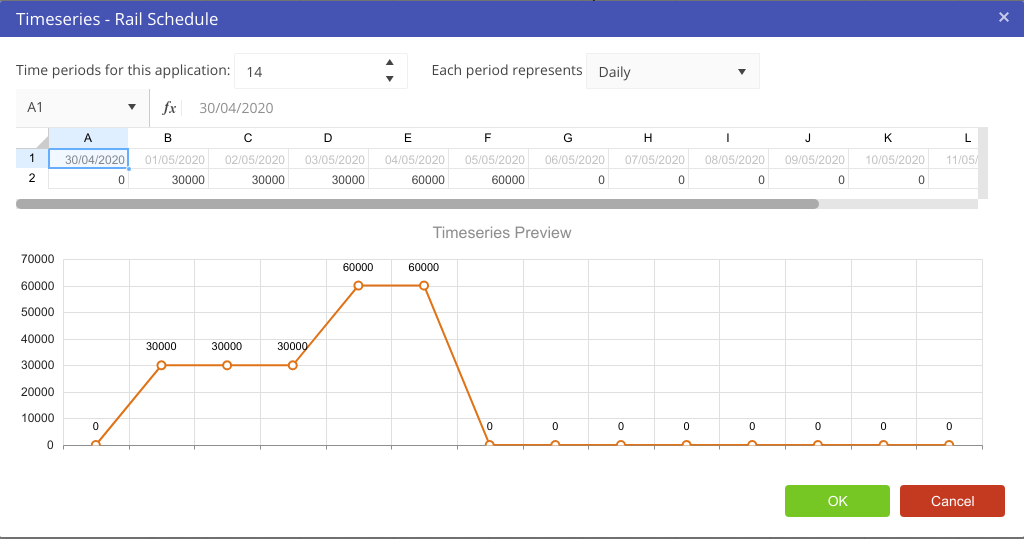

- We know we need 300,000 tonnes by period 6, we start off with 150,000 tonnes at period 1. What if we rescheduled more trains in the leadup to the ship coming in? We’re still keeping the same number of trains, just moving delivery (of course this also depends on our own infrastructure, distance between the Mine and Port etc). Alter the rail schedule to look as follows:

- As we step through time, we get to 210,000 in the port at period 3, then stepping to period 4, we’re still on 210,000 tonnes, and Railed Tonnes is 0. We know we’ve scheduled a train, so why isn’t it picking up any ore. Looking at the Port Stockpile max size, we’re nowhere near it.

- Go back to the Crusher page, and we can see that the crusher has stopped producing. The maximum stockpile size on the crusher hasn’t been hit, so look at the ROM. It’s 0 - we don’t have enough throughput on the mine side to service the increase in demand.

- Go to the Mine - we need to increase the number of trucks as well.

- Clone the Increase Rail Schedule scenario, and call it Increase Rail Schedule And Trucks

- Set the Trucks scope to Scenario, and the number of trucks to 4. At period 4, the Trucked Tonnes is 0. So although we’ve added more trucks, we’re limited by the Crusher throughput - the ROM size will be more than the amx size of 80,000.

As you can see, every action you take has an effect somewhere within the supply chain. It takes an intense understanding of your own process, but with the power of Akumen at your disposal, you can examine different scenarios to get the most of out of your process, without investing heavily in infrastructure that may or may not work, or have unintended consequences.